A Closer Look at the PVEL Product Qualification Program (PQP)

Buyers around the world rely on PVEL’s Product Qualification Program (PQP), a series of extended reliability tests, to help inform procurement decisions. Learn more about the PQP program, and how it helps mitigate risk for the solar industry.

The vast majority of the solar sites operating today are less than 5 years old. Without long-term field data, buyers have often relied on basic certification testing to make their procurement decisions. However, basic certifications only guarantee that products are minimally safe and free from obvious defects. They do not test for long-term performance.

Although solar projects are planned with sophisticated revenue and energy yield models, these models are only as accurate as the data behind them. PV Evolution Labs (PVEL), a Member of the Kiwa Group, provides independent testing of solar photovoltaic (PV) modules and equipment through a series of extended reliability and performance tests known as the Product Qualification Program (PQP). Our PQP replaces performance assumptions with empirical metrics, allowing project developers, investors, and other downstream solar companies to access reports that strengthen their technical due diligence.

As the industry’s leading independent lab, PVEL has tested over 500 unique module Bills of Materials combinations (BOMs) from more than 75 manufacturers and amassed over a decade of performance and reliability data. From this experience, we know that that small changes to a solar modules’ BOM can have a meaningful impact.

Tests in the PQP

Our PQP begins with factory production witnesses, a service provided by fellow Kiwa Group Member, PI Berlin. No handpicked samples are allowed: the production of all BOMs submitted to PQP testing are witnessed by our auditors. Factory witnesses oversee every step of the PV module production process, from the opening of raw materials packages to wrapping a completed pallet in tamper-proof tape.

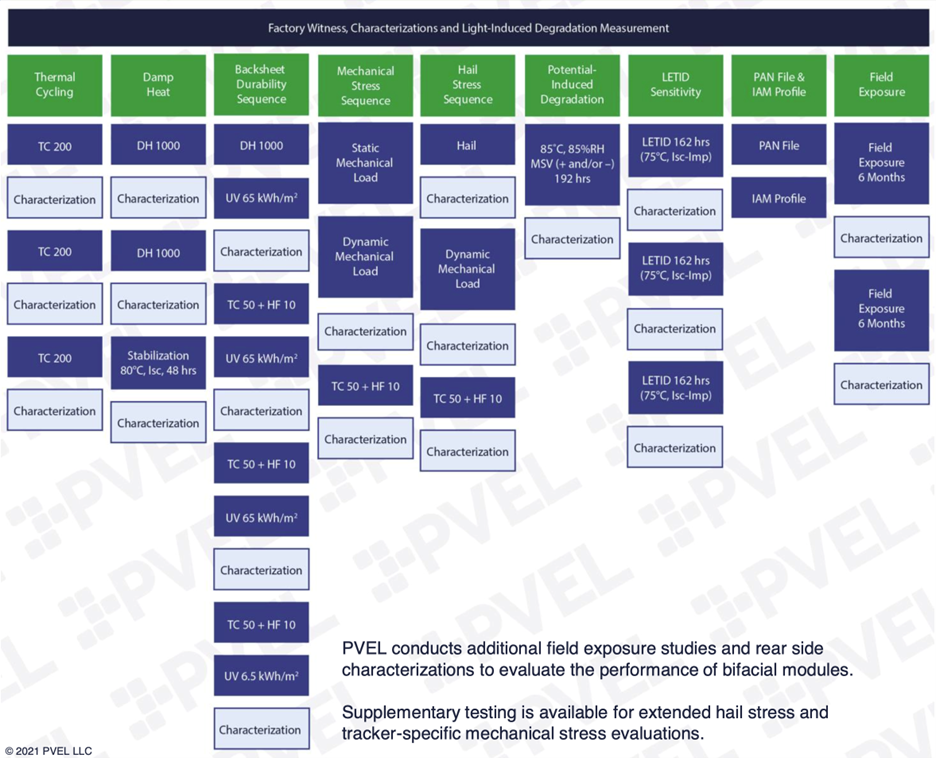

Once they arrive at our labs, each BOM undergoes a unique sequence of testing designed by PVEL. These include:

• Thermal cycling

• Damp heat

• Backsheet durability sequence

• Mechanical stress sequence

• Potential induced degradation

• Light induced degradation

• Light and Elevated Temperature Induced Degradation (LETID)

• Hail stress sequence

• PAN file measurement and generation

• IAM measurement

• Field exposure & performance

These test streams evolve based on feedback from PVEL’s downstream partners, module manufacturers, and the industry’s collective understanding of module failure modes and test mechanisms.

Additionally, every solar BOM is tested in the same way using calibrated equipment and in consistent laboratory environments, enabling a levelized comparison across BOMs and manufacturers. The reports in our PQP are complimentary for companies that sign up as PVEL’s downstream partners and join our network, helping to support Kiwa’s mission to create trust around the world.

As technology advances, new data from the field becomes available and research is conducted, PVEL gathers feedback from the market that informs periodic updates of our PQPs. This process ensures that our testing continues to generate the data that matters for solar deployment.

Learn more about the Scorecard

In our annual PV Module Reliability Scorecard (available at scorecard.pvel.com) we highlight the manufacturers who produce PV modules with excellent results in our PQP testing, including a searchable database of model types. Visit scorecard.pvel.com to explore more about PVEL’s testing, Top Performers, case studies, and more!

Learn More

Curious about how PVEL's testing and technical services can help your company mitigate risk, optimise financing, and improve system performance throughout the solar project lifecycle?

Click here to learn more.

Contact

388 Devlin Road

Napa, CA 94558

USA

+1 415 320 7835

info@pvel.com