Why UVID testing matters

Historically, UV degradation of PV modules was primarily associated with yellowing of encapsulant and backsheet polymers. More recently, the UV induced degradation vulnerability of high-efficiency modules has been top of mind in the industry due to the increased cell sensitivity to high-energy UV radiation. Research has shown that one the main mechanisms of UVID degradation is damages to the cell passivation layers and interfaces with the silicon bulk caused by UV light.

The equivalent 120 kWh/m2 of front-side UV exposure, with test samples in short-circuit condition (Isc) and a temperature of 60°C, will allow modules buyers to understand if modules are susceptible to UVID in a relatively quick and economical test. This test duration is equivalent to approximately one or two years of field exposure, depending on the location, and is intended to provide a screening method for assessing the suitability of the manufacturer’s warranty conditions. The test is not designed to measure the full amount of UV-related degradation of PV modules, which would require a much longer UV exposure.

While several researchers have observed a higher degradation when performing rear-side UV exposure, it is important to note that even optimized bifacial systems see an average of less than 10% bifacial gain. Of this rear side irradiance boost, only a limited amount falls within the UV spectral region, so one would expect the annual UV dose on the rear side to be lower than the front side by a factor greater than 10. Thus, Kiwa PVEL’s UVID test has been focused on the most impactful metric which is front side power degradation.

|

|

|

UVID results from PVEL’s recent testing of randomly selected modules shows a range of susceptibilities and power loss. Note: results are not a statistically significant sample of each cell technology and other results may vary. |

|

|

| Post-UVID120 change in EL image for a UV-sensitive PERC module. |

Materials assessed

|

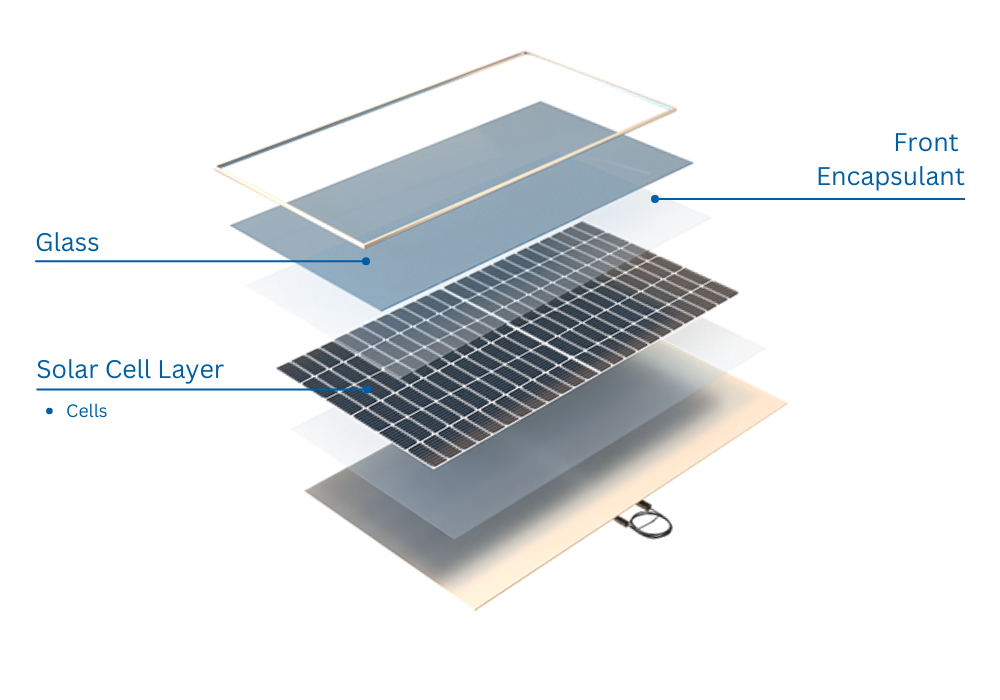

While Kiwa PVEL’s UVID test probes cell-level degradation mechanisms, the layers in front of the cells can impact the level of UV passing to the cells. Therefore these materials influence a PV module’s UVID susceptibility:

|

|

Test procedure

| Following the guidance of IEC 61215:2021 MQT 10, the module is subjected to a front-side UV dose equivalent to 60 kWh/m2 in a UV chamber capable to maintain the modules at a temperature of 60°C. The module is subjected to two rounds of these conditions, for a total front-side UV dose equivalent to 120 kWh/m2. |  |