Why field exposure testing matters

Kiwa PVEL’s field exposure testing is designed to reproduce typical installation and operating conditions for a PV module, and characterize its performance in a real-world environment for an extended duration. This is important considering that the other PQP tests subject modules to a limited number of stresses simultaneously (such as temperature and humidity, or temperature and current injection), whereas in field applications modules can be subjected to all stresses simultaneously (including current, maximum system voltage, thermal cycling, UV, high temperature, humidity, poor handling/transportation damage, extreme weather, wind loading, etc.). As first year power warranty values become more aggressive, with some n-type modules having a warranted 1% year-one degradation, validating this value through distinct PQP stress tests is somewhat achievable, but placing the module outdoors for one year provides strong evidence as to whether the advertised year-one degradation amount is achievable.

An unique benefit for Kiwa PVEL’s field exposure testing is that it occurs at the historic PVUSA outdoor test facility in Davis, CA. This allows seamless ASTM E2848-13:2018 capacity testing analysis to be performed to calculate PV system DC power values at PTC and corresponding PTC ratios. ASTM E2848 DC Power at PVUSA Test Conditions (PTC) is a common way of evaluating PV system performance to “normalize” for continuously varying weather conditions (leading to continuously varying PV system output). Continuously-monitored PV system power output and concurrent weather measurement data collected during field exposure testing are analyzed over each month, and a single DC power value is derived at PTC (1,000 W/m2 plane of array irradiance, 20 °C ambient temperature, and 1 m/s wind speed), which are more field-representative than STC (especially for the PVUSA test site). Dividing the monthly PTC power values by the corresponding module’s STC rating yields what is referred to as the “PTC ratio”. Investigating time series of monthly PTC power values or corresponding PTC ratios reveals insights on PV system power degradation trends. PTC ratios also provide a way to benchmark the performance of different module types of given module types and/or BOMs relative to one another.

Materials assessed

|

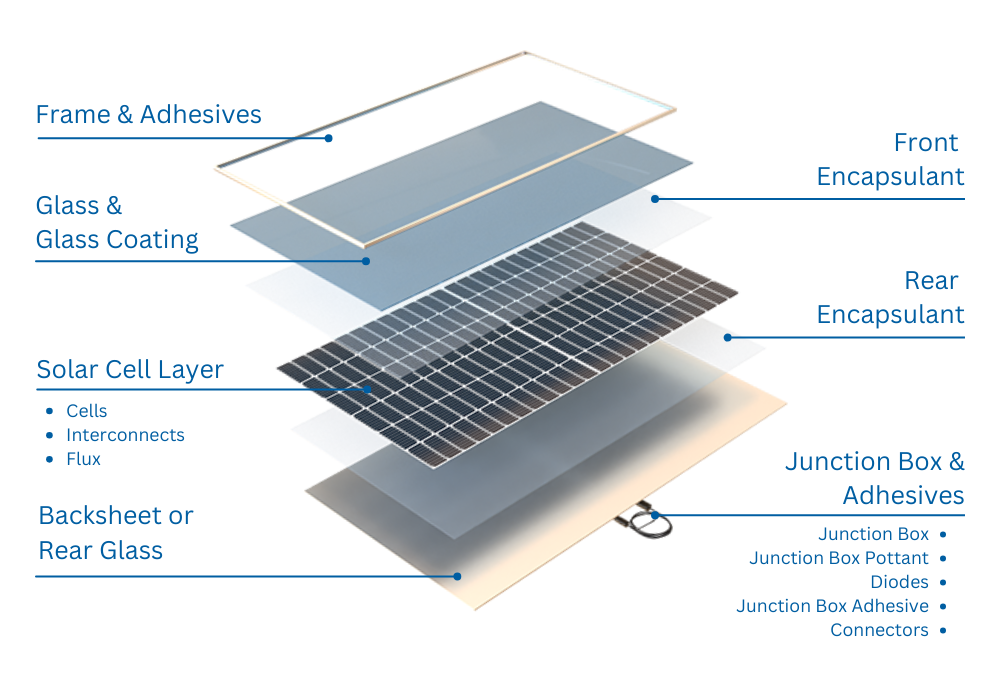

The one-year field exposure test probes the initial performance and reliability of all of the PV module’s materials and their various interactions. |

|

Test procedure

|

FE modules are installed outdoors directly after initial characterizations. They are then characterized after six months and again after twelve months. The installation type is dependent on the module type with smaller modules typically installed on Kiwa PVEL’s mock residential rooftops and larger modules installed on fixed tilt groundmount racking. Each module is connected to an individual microinverter for maximum-power point tracking. The DC output of the module is monitored via Kiwa PVEL’s custom-made data-acquisition system (DAS). Data is also available collected from the weather instruments on site, including: GHI (global horizontal irradiance), POA (plane of array) irradiance, wind speed, ambient temperature and precipitation. After each six month period, Kiwa PVEL uses the continuously monitored weather and energy production data to compute monthly power capacities per ASTM E2848-13:2018, at a defined set of reporting conditions of global plane-of-array irradiance, ambient temperature, and wind speed. These are included in the reports along with energy yield and characterization data. Note: FE testing is optional when conducting a PQP. |

|