The MPA performance test is divided into two test parts as follows:

- Part 1 Acid test (storage at pH = 3.5 for 12 weeks)

- Part 2 Holistic Approach (holistic description of performance)

- Part 3 Lifetime consideration (probabilistic approach)

The Acid test

The principle of acid testing is based in its entirety on the general characterization of the impermeability of concrete as a material and the direct verification of resistance to attack by sulfuric acid. The method operates at a constant pH of 3.5 with an immersion time of 12 weeks in the acid test facility (see figure below). In all tests, a high-performance concrete is included as a reference concrete (concrete with the highest possible acid resistance) for comparison purposes.

Figure: Test facility for storing the specimens in acid

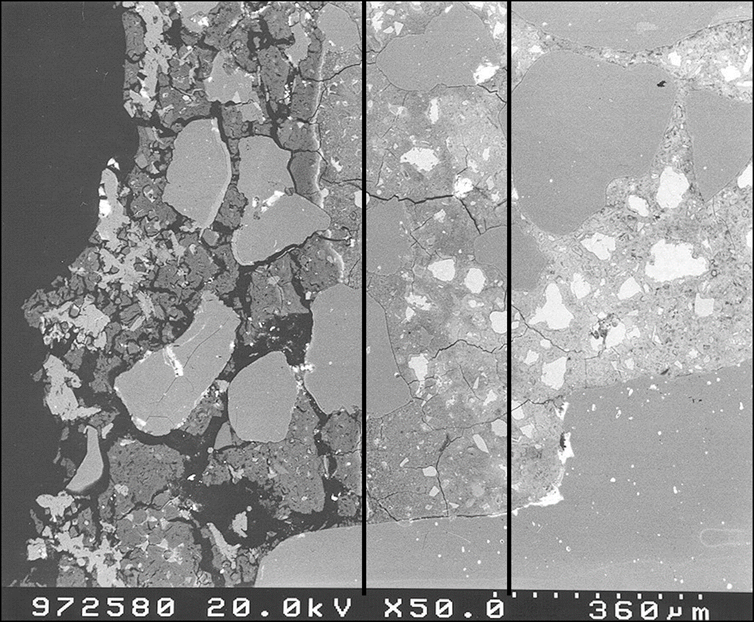

A major strength of the method is that the depth of damage to the concrete is directly visualized by microscopic methods and quantitatively determined in mm/stress period (see following figure).

Figure: First and second damage front (SEM image on thin section).

Part 2 Holistic Approach

The testing part of the Holistic Approach also describes the overall performance of the concrete, the following performance characteristics are examined in this framework:

- Determination of the microcracking tendency of the binder matrix . This has a decisive influence on the long-term durability. The determination of the microcracking tendency is carried out by determining the frost (de-icing salt) resistance as an auxiliary variable,

- Determination of sulfate resistance via the SVA method (test duration: 91 days),

- Determination of porosity parameters (total porosity and cumulative pore volume in the range < 100 µm) to evaluate the impermeability to dissolved pollutants,

- Determination of chloride penetration resistance (risk of pitting corrosion),

- Determination of residual alkalinity (corrosion protection of steel reinforcement).

In order to be considered a formulation of the highest resistance and impermeability, the following requirements, which are specified in the Additional Technical Terms of Contract (ZTV) for concretes with increased acid resistance, e.g. by the Emscher Genossenschaft water board or at Berliner Wasserbetriebe, Lausitzer und Mitteldeutsche Bergbau-Verwaltungsgesellschaft (LMBV) or the Association of Large Boiler Owners (VGBPowerTech), must be met in their entirety:

| Test method | Requirements (limit values) |

| Evaluation by depth of damage | ≤ 1.3 mm |

|

Test for evaluation of microcrack tendency via determination of the freeze-thaw resistance (CDF) after 56 cycles |

Reduction of the dyn. modulus of elasticity: 40%. Mass loss: 1,500 g/m2 |

| Sulfate resistance via the SVA method | < 0.5 mm/m |

| Total porosity | < 11 vol.% |

|

Cumulative pore volume in the range < 110 µm Average pore radius |

< 40 mm3/g < 0.1 µm |

| Chloride migration coefficient | < 1.0*10-12 mm2/s |

| Residual alkalinity, based on binder | > 3 g Ca(OH)2/100 g binder |

Part 3 Lifetime analysis (probabilistic approach)

Based on the results of the MPA performance test, a service life assessment (Part 3) can also be carried out according to a probabilistic approach, for example if the performance of the products has to be proven by testing for maximum stress scenarios and for life expectancies of up to 100 years. In this way, repair work can be reliably planned for the long term and downtimes reduced."

References

In recent years, Kiwa GmbH, MPA Berlin-Brandenburg has been involved in the planning of many major projects in this field of application:

- The MPA performance test was applied, among others, in the Emscher project, the largest construction project in the field of wastewater engineering plants in Germany in the last 30 years (planned service life: 120 years, € 4.3 billion construction sum). We were involved here both in an auditing capacity and in an advisory capacity,

- The Deep Tunnel Sewerage System II (DTSS Phase II) construction project in Singapore is currently being supported in a similar way,

- further major projects have been successfully implemented with the leading concrete manufacturers or operators of wastewater engineering plants, both in the in-situ concrete as well as in the ready-mix and precast industry,

- the last ten cooling towers of large power plants were accompanied in terms of material technology and quality assurance, worldwide we are involved in the construction of these cooling towers, which have an acid environment as a permanent exposure,

- in the course of the renaturation of opencast lignite mines, a very important current topic in Germany, countless investigations have been carried out. Concrete structures exposed to the acidic water of flooded open-pit mines have been designed according to their intended service life.

The MPA performance test is a "normative" test method covered by the European Technical Assessment Document EAD 180009-00-0704. Based on this document, European Technical Assessments (ETA's) are issued for "acid resistant" concrete pipes as an extension of DIN EN 1916:2003-04.

Questions? Feel free to contact us

| Dr Ronny Stadie | ronny.stadie@kiwa.com | +49 163 546 09 79 |

| M.Sc. Tom von Minding | tom.von.minding@kiwa.com | +49 163 546 77 02 |

| Dipl.-Ing. Carsten Rieck | carsten.rieck@kiwa.com | +49 163 546 77 01 |